360 factory tour

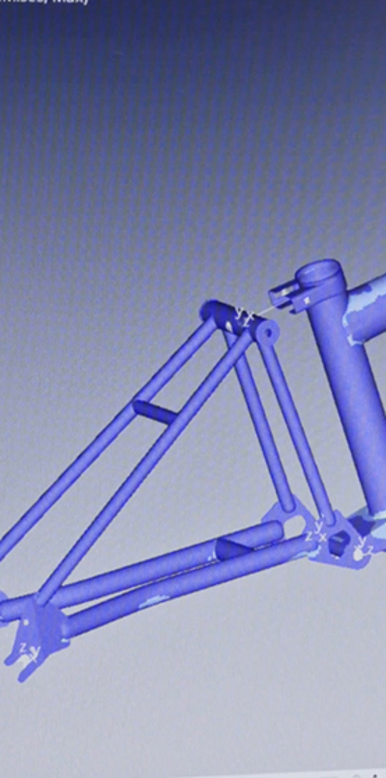

Brompton is defined by the ingenious engineering of our founder Andrew Ritchie. And by the collective courage to do things differently. Across our West London factory and expert welding division in Sheffield, a team of 300+ engineers, designers, skilled fabricators, makers, inventors and manufacturers work to make the world's best folding bike.

See how we do it in the 360-degree factory tour.